|

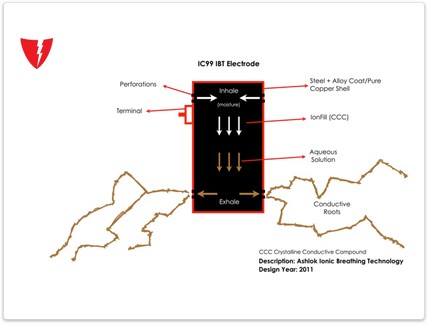

Ionic Breathing Technology (IBT)The IBT or the Ionic Breathing Technology has been developed to meet the need so earthing in harsher environments. The design of the system has added a dynamic element in the functioning of the electrode. The terminal end incorporates perforations which is complemented by similar perforations at the bottom end. The cavity in-between the electrodes is filled with IonFill which contains hygroscopic elements. These elements capture the moisture from the surrounding environment and 'inhale' it from the terminal end. This moisture mixes with the IonFill forming a concentrated aqueous solution which is electrically conductive and steadily Dlows down due to gravity, 'exhaling' out through the bottom end. Once exhaled, it flows through the soil and forms conductive roots around the electrode increasing the effective surface area.

|

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

ASEEL HDG* Hot dip galvanized for corrosion protection * Pipe In Pipe Design * Designed for fast fault current dissipation * Low maintenance earthing system * Easy & fast installation on site * Most suitable for soil condition with pH value between 5.0 & 8.0 * Crystalline Conductive Compound: CompactFillâ„¢ * Ashlok Designed Production Process

|

||||||||||||

|

Ashlok Designed Production Process (ADP)Since earthing systems face different kinds of soil, climatic & electrical environments around the world, it is extremely important that they are manufactured with extreme care, precision and quality. Defects like varying coating levels on the electrode surface can hamper service life. Improper ratios of CCC components can lead to varying resistance results. At ASHLOK, we took up the challenge to design our own production processes for the different metallic coatings, internal cavity compound Dillings and packaging. Today, we have our own production systems in place to constantly meet 'A' grade quality norms we have set for ourselves. This is helping us to serve you better - everyday.

|

||||||||||||

|

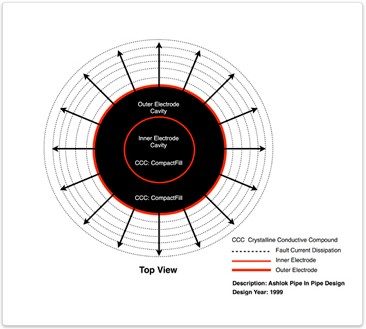

Pipe In Pipe Technology (PiP)Pioneered by ASHLOK in 1999,the Pipe In Pipe design incorporates the use of two pipes of co-axial diameters joined together for enhancing the service life and performance of the over all earthing system. The cavity in-between the electrodes is filled with crystalline conductive compounds IonFill or CompactFill for current dissipation and anti corrosive properties. The electrode cross section has to be circular for the uniform distribution of fault current all around from electrode to earth. Available in the following sizes

|

||||||||||||

|

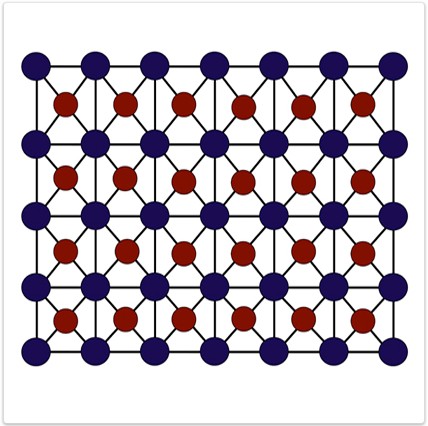

Crystalline Conductive Compounds (CCC)

CompactFill (COMPACT)The volume between the inner and outer pipes of the electrode is occupied by CompactFill, a compound formula developed by ASHLOK which aids in increasing the electrical conductivity, service life and current with-stand capacity of the earthing electrode. It constitutes elements picked up from nature and is anti corrosive too.IonFill (ION)This is the latest compound formula developed by ASHLOK for the IC99 range of earthing electrodes. The internal cavity of the electrode is occupied by IonFill which constitutes elements which aid in the breathing action of the electrode. They form an integral part of the functioning of the electrode as they trap moisture from the surroundings and enhance electrical conductivity. Through the breathing action of the electrode, they form conductive roots all around the earthing system. CompactFill & IonFill play a crucial roll in the functioning health of the electrode and it is very critical that they are produced in exact proportions and filled with scientific care. A small void in the internal cavity of the electrode can cause Dluctuations in results.For that reason, all the electrodes undergo an ASHLOK designed precision process for the deposition of CompactFill/ IonFill into the internal cavity keeping in tune with our quality policy.

|

||||||||||||

|

ElectroditeIt houses all the properties that an ideal BFC should have constituting natural elements, it reduces soil resistivity, helps retain moisture and is an efficient soldier in the dissipation of fault current. It is hygroscopic in nature and swells when it comes in contact with water thereby engaging constant contact between the electrode surface and soil which is crucial in the performance of an Earthing system. Best for normal soil conditions.

|

||||||||||||

|

LIGHTNING ARRESTORSTHOR LPR

|

Safe Earthing Electrodes Pvt Ltd

Safe Earthing Electrodes Pvt Ltd

Call Us : +91 94440 87356 Email Us : earthing@ashlok.in